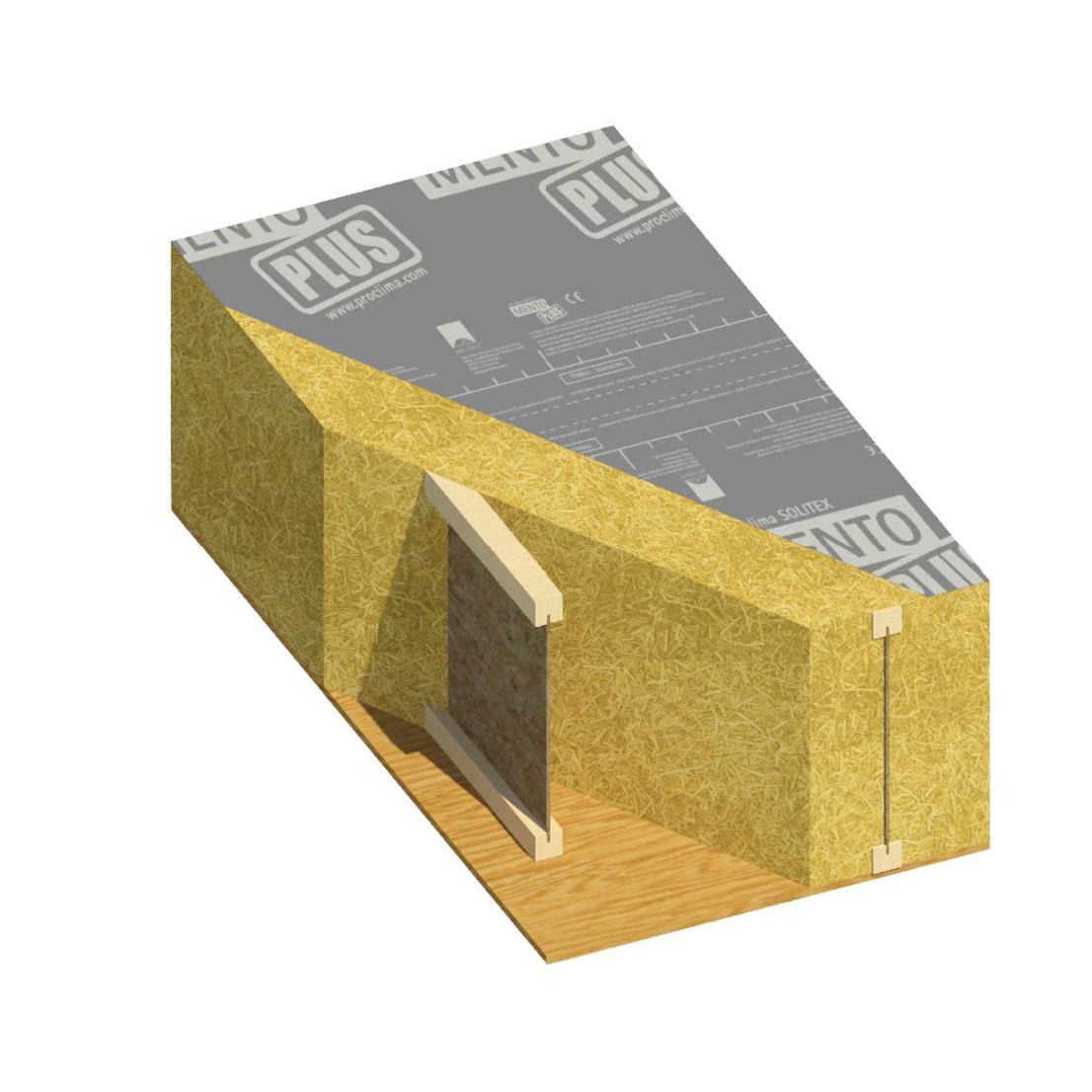

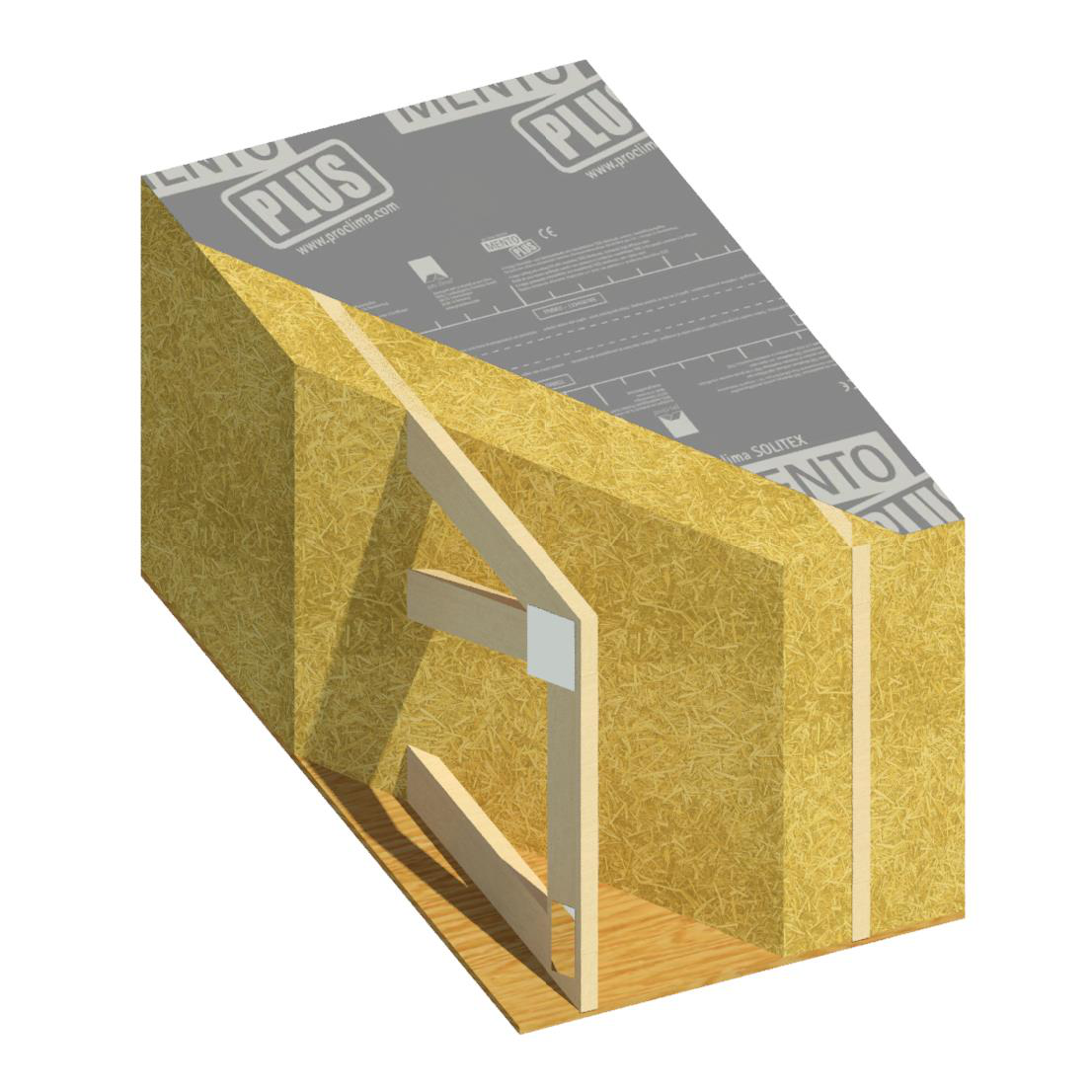

Prefabricated straw panels are most commonly used on projects that prioritize energy efficiency and long term resiliency. Our customers often value a transparent, low energy supply chain that enables unparalleled carbon storage in the built environment.

While it is critical that the panels themselves are properly fabricated, it is also important to consider how prefabricated construction influences other areas of your project. Architectural design, structural requirements, and logistics constraints are key considerations in comparing site built or panelized construction. Not every project is the right fit for ‘prefab’, whether straw insulated or conventional. We always encourage an early conversation with a Savick Designer to discuss the feasibility of our involvement in your project. Some helpful information on preparing to work with Savick is described in our Prefab Planning Guide.

Savick plays a key role in the preconstruction process; often taking the lead with the project's structural and envelope engineering. While Savick Shapes offers a more streamlined approach for planning your next project, custom design offers greater flexibility and creativity. If you are just beginning your custom design process we are happy to connect you with a number of architects or designers who are already familiar with Savick’s technical details and processes. We are also always happy to start a new collaboration if you are already working with an architect new to Savick Assemblies.

Listed prices are subject to change with notice, and are intended for budgetary purposes only. Final costs may be influenced by project complexity and commodity pricing. The most accurate way to get a free estimate for your project is to meet with a Savick Designer.